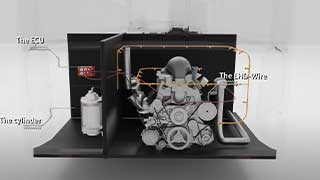

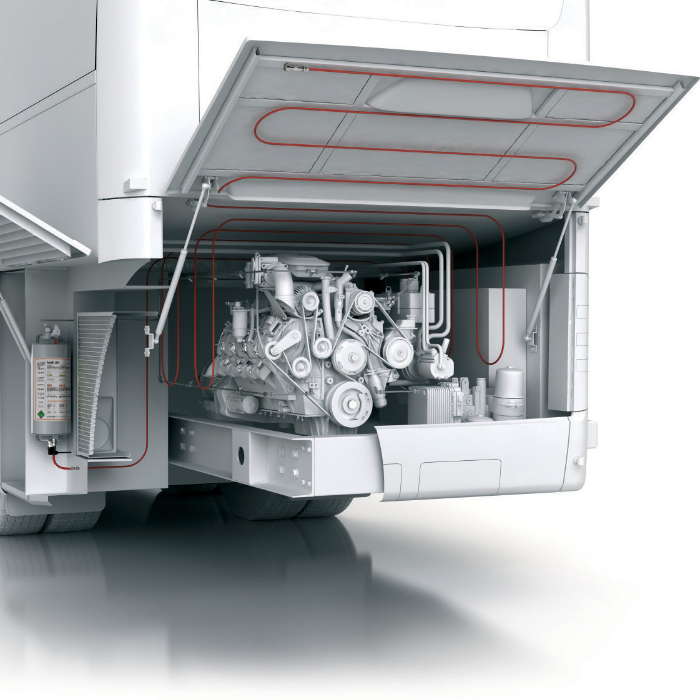

A COMPLETE PRE-ENGINEERED FIRE SUPPRESSION SYSTEM FOR VEHICLE ENGINES COMPARTMENTS

A COMPLETE PRE-ENGINEERED SYSTEM

Designed to protect vehicle engines from fireEverything you need together in one box

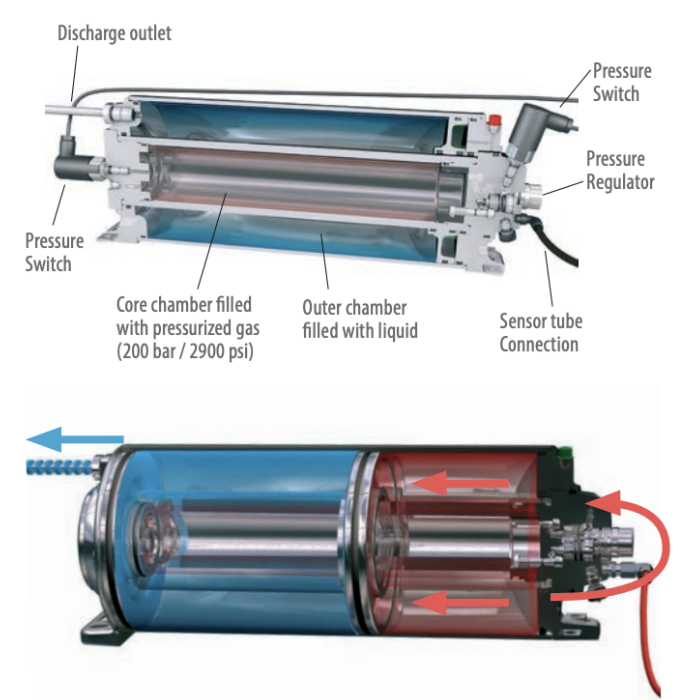

FULLY AUTOMATIC

Automatically detects and suppresses fireNo power supply required for activation

UNECE R107 and RISE APPROVED

Tested and Certified according to UNECE R107 Standards for passenger bus enginesULTRA-COMPACT

The most compact system to obtain the UNECE certificationProtects engine compartments of 4m3 with just 4 L of agent